Magnet plating knowledge

Magnet plating is an important factor in the appearance and storage time of the product. The surface treatment mainly includes zinc, nickel, copper, chromium, gold, black zinc and epoxy resin. Its surface plating is not the same, its color is not the same, its preservation time is not the same, each has its own advantages and disadvantages.

1) Zinc: The surface looks silvery white. It can be used for 12-48 hours of salt spray. It can be used in some glues. (such as AB glue) If it is plated, it can be stored for two to five years. The advantage is price comparison. low.

2) Nickel: It looks like stainless steel color. It is difficult to be oxidized when it is left in the air. The appearance is good, the gloss is good, and the plating can pass the salt spray test for 12-72 hours. The disadvantage is that it cannot be bonded to some glue, which will cause the coating to fall off. Accelerated oxidation, now the market is mostly nickel-copper-nickel plating method for 120-200 hours salt spray, but its plating cost is relatively high.

3) Copper: It appears in the hardware industry. The NdFeB industry is rarely used, and its appearance is yellow.

4) Chromium: The chromium plating industry is also relatively rare, and its plating cost is high, and the general company cannot accept it. However, its ability to release rot is very strong and it is difficult to react with other substances. Mainly used in places with strong acidity and alkalinity, domestic products are relatively low in price, so there are few people to choose.

5) Black zinc: It is processed according to customer's requirements to black surface. In the electroplating process, it is mainly based on galvanizing and chemical treatment with a black protective film. This film can also protect the product. Increase the salt spray time and prolong the oxidation time. However, its surface is easily scratched and loses its protective effect. There are very few people who use it now, and most of them are replaced by resin. Below we have instructions.

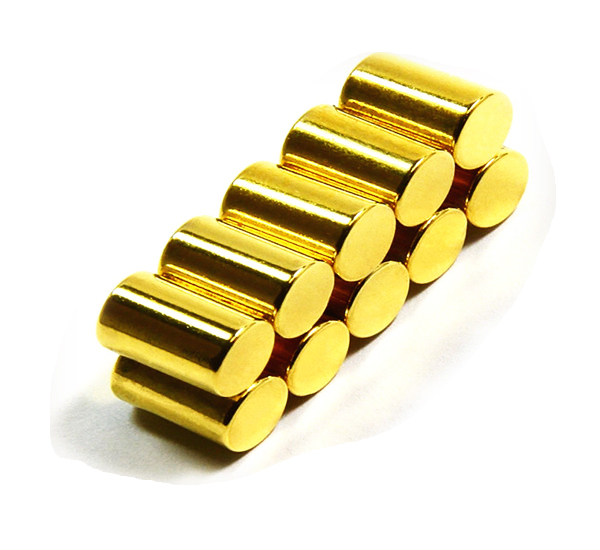

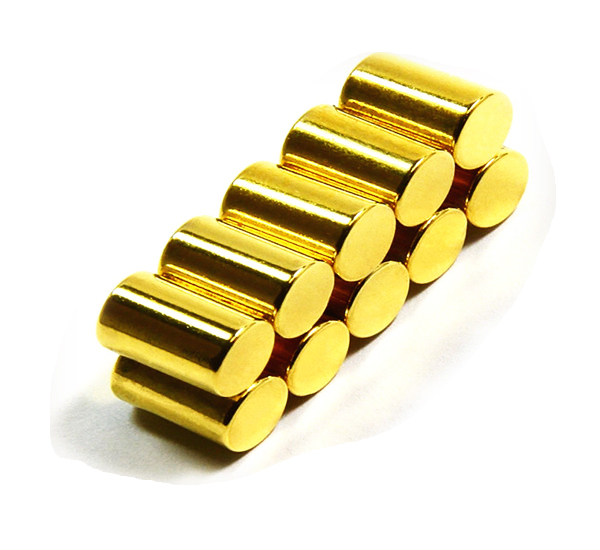

6) Gold: This industry is very popular nowadays. Most of the yellow gold ornaments we saw on the streets are gold-plated or copper. Gold plating makes the appearance of the product look very beautiful like gold. It is generally used in the jewelry industry. Our products can also be gold plated for magnetic jewelry.

7) Epoxy resin: After the product is nickel-plated, a layer of resin paint is added on the outside. This industry has only had a market in the past two years, and its development speed is very fast. Now there are many people who use various electroplating products, and the largest one. The advantage is that you can do what you want.

The white film inspection is our last smooth operation. Here we have to check all the non-conforming products and magnetize them according to the requirements, and then put them into the warehouse.

Tags: neodymium magnets Neodymium magnets£¨NdFeB magnet£¨block magnet Smco magnets